Legionella Control

Are you fully compliant with the latest Legionella Legislation requirements?

Do you have potential Health & Safety Risks?

Do you know how safe your water is in your building?

Do you have concerns you are not doing enough?

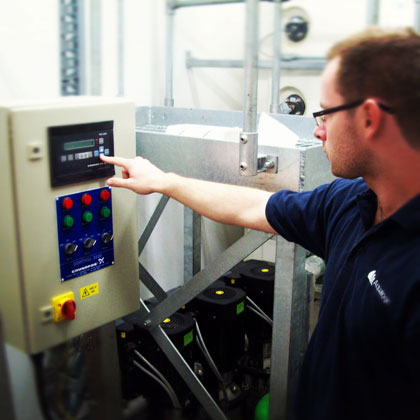

Lakeside water have extensive experience and are passionate in Legionella control which incorporates:

- Legionella water hygiene risk assessment and schematic drawings

- Water hygiene monitoring, log book and reporting

- Planned analytical service visits

- Live web based Legionella log books and bespoke site records

- Microbiological sampling for all water bourn microorganisms by a UKAS independent lab sampling to BS7592

What are the facts?

Legionnaires Disease

- Legionnaires disease is potentially fatal, first identified in Philadelphia in 1976 at a American Legion convention

Legionella Bacteria

- Found in the natural environments, rivers & lakes

- It can survive between 6°c & 60°c

- It favours growth between 20°c & 45°c

- It remains dormant in cool water

Legionella to Legionnaires Disease

- Contracted by inhaling the bacteria in the form of tiny droplets of water (aerosols) and droplet nuclei (particles left after water has evaporated).

Who is at risk?

- Everyone

- The young and the elderly

- People with Illness

- People with low immunosuppression

- People who smoke

What are the risks?

- Spray taps

- Showers

- TMV's Thermostatic Mixing Valves

- Hot & Cold water

- Cooling Towers

- Humidifiers

- Spas and Pools

The Legislation

- Health and Safety at Work Act 1974

- Management of Health and Safety at Work Regulations

- Control of Substances Hazardous to Health (COSHH)

- Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 1995 (RIDDOR)

- Notification of Cooling Towers and Evaporative Condensers Regulations 1992

The Approved Code of Practice (L8)

- The code gives advice on the requirements of the Health and Safety at Work Act 1974 and the Control of Substances Hazardous to Health 1999 (REGS)

- ACOPS material has special legal status

- If you follow the advice in the approved code of practice then you will be doing enough to comply with the law

- If you get prosecuted for breach of Health and Safety Law, and you did not follow the Code, you need to show you have complied with the law in another way

- Following the guidance is not compulsory and you are free to take other action. But if you do follow the guidance you will be doing enough to comply with the law. Health and safety inspectors seek to secure compliance with the law and may refer to the guidance as illustrating good practice

Failure to Comply / Manage, What are The Potential Penalties?

- Fines? Could class as corporate manslaughter?

- 10% of annual turnover

- Imprisonment?

- Accountable from delivery to direction

What is required to comply?

- A Suitable and Sufficient Risk Assessment is Required to Identify and Assess:-

- The risk of exposure to legionella bacteria from work activities and water systems on the premises

- Any necessary precautionary measures to prevent and control the risk

- Responsible Person for site appointed

- Ensure competency & training

- Create, complete and update site water hygiene log book

- Keep adequate records, of all water activities

- Confirm competency of staff, consultants and contractors

- Confirm contract details

- Implement written scheme

Monitoring - Record Keeping

- Weekly

- Hardness checks to monitor whether the water softener is passing soft water to service.

- Flushing of rarely used outlets, including showers.

- Monthly

- Record calorifier storage temperatures, and temperatures of the return line to monitor whether the calorifier is storing water at 60°C or above and that hot water is returning to the cylinder at no less than 50°C.

- Record monthly hot and cold outlet temperatures. Hot water should be supplied to outlet within one minute of running at no less than 50°C. Cold water should reach outlet at 20°C or below within two minutes of running.

- Quarterly

- Calorifiers should be blown down to reduce sediment build-up, which can produce a suitable environment for bacteria. The drainvalve should be opened for two minutes or until the water runs clear.

- Showerheads and hoses must be dismantled, cleaned, disinfected and descaled as necessary.

- Six Monthly

- The storage temperature of cold-water storage tanks should be recorded along with the general condition of the tank.

- Annually

- Whenever practicable calorifiers should be internally inspected and cleaned as required, followed by a chlorination or a thermal pasteurisation.

We can help

Lakeside water are members of the LCA (Legionella Control Association), we have a dedicated team who fully understand the requirements and can assist to make sure that all our clients meet the required Health & Safety standards to comply with current legislation and guidelines

Call today for a free consultation or site audit

Tel: +44 (0) 1733 245032